The Incredible World of Lathe Machines

Lathe machines have transformed manufacturing processes. These tools create precise parts from various materials. As technology advances, lathe machines evolve, enhancing efficiency. They remain crucial in modern factories. This blog explores the features, applications, and future of lathe machines.

Moreover, the versatility of lathe machines makes them a favorite in various industries, ranging from automotive to aerospace. With the ability to rotate a workpiece against cutting tools, these machines offer remarkable accuracy and efficiency. As materials like metal, wood, and plastic are shaped and sized, the finished product often reflects the craftsmanship and precision that lathe machining embodies.

In addition to their effectiveness, lathe machines come equipped with a variety of features that cater to different machining needs. For instance, the advent of computer numerical control (CNC) technology has changed the landscape of lathe machining. By utilizing automated operations, CNC lathes allow for faster production times and reduced human error. Transitioning from manual to CNC lathes has brought about a revolution in how components are produced, leading to a surge in demand for skilled operators.

As we delve deeper into the world of lathe machines, we’ll uncover the essential types, operations, and maintenance practices that ensure optimal performance. Whether you’re interested in learning the basics or seeking advanced techniques, this comprehensive guide will serve as your roadmap. Join us as we embark on this fascinating journey, and discover how lathe machines continue to shape the future of manufacturing and craftsmanship.

Understanding Lathe Machines

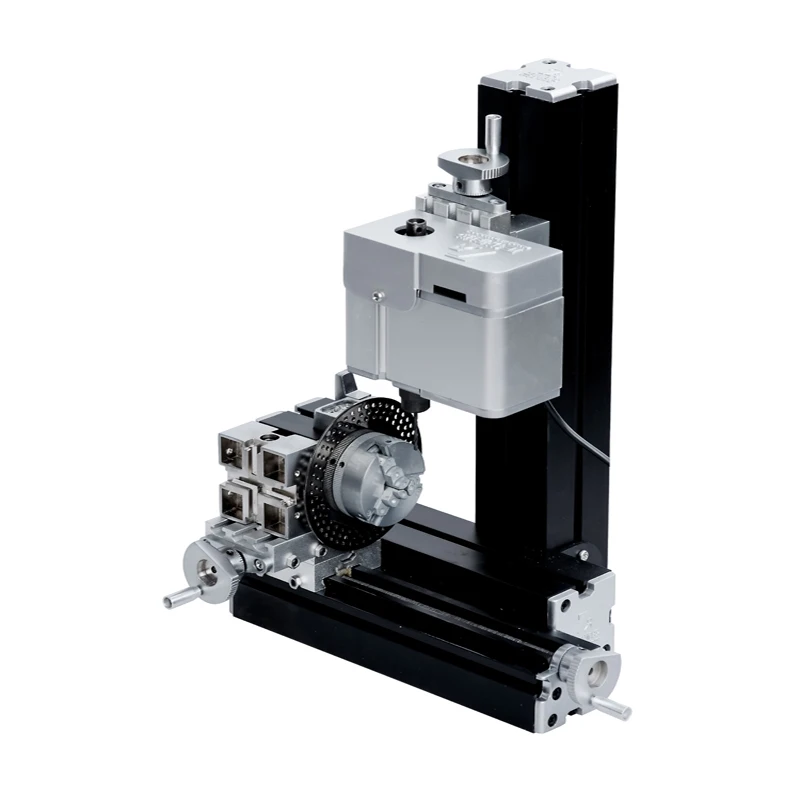

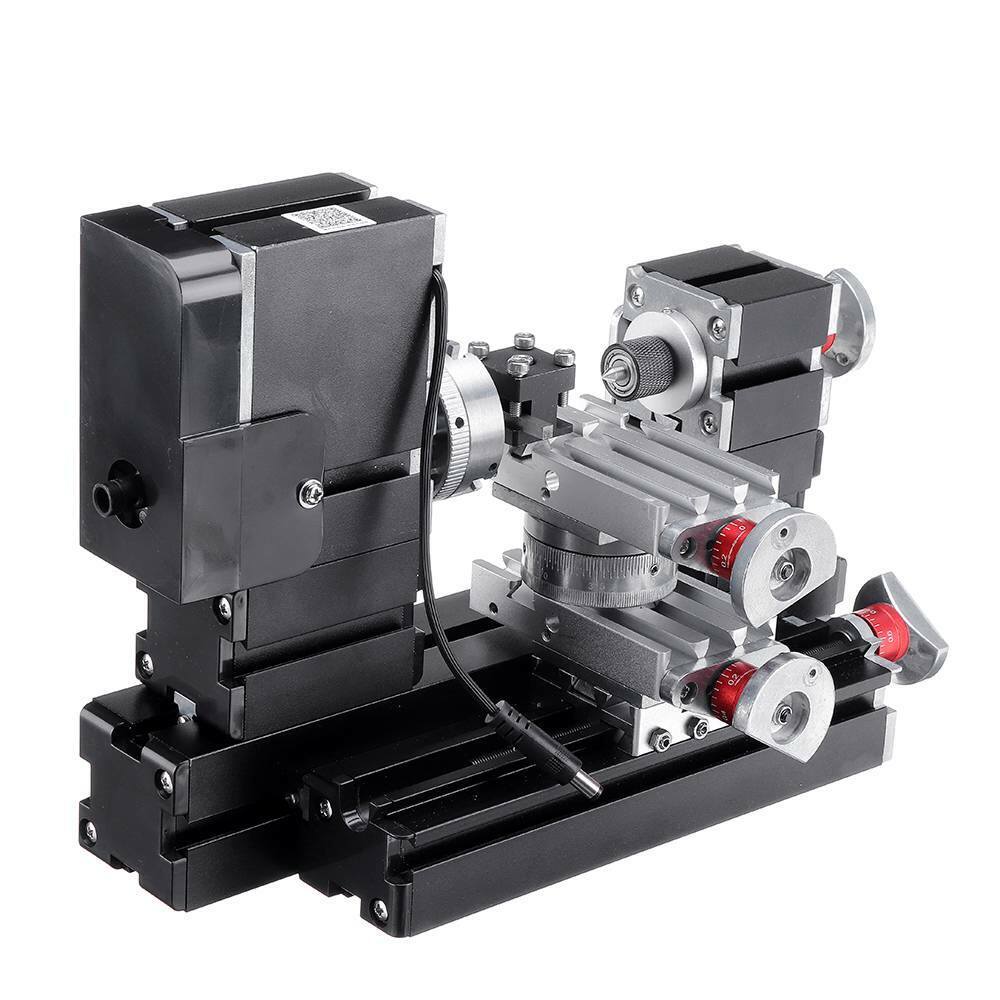

Lathe machines operate on a simple principle. They rotate the workpiece against a cutting tool. This rotation allows smooth shaping and cutting of materials. Both metal and wood can be shaped using lathes. Variable speeds enable the handling of multiple material types. These versatile machines cater to diverse industries, from aerospace to shipbuilding.

Lathe machines come in different types. Every type suits specific applications. For example, engine lathes are general-purpose tools. They often serve in workshops for numerous tasks. On the other hand, CNC lathes employ computer controls for precision. This latter type enhances productivity and reduces human error.

Furthermore, lathe machines can create various shapes. Common forms include cylinders, cones, and spheres. By adjusting the cutting tool’s position, operators achieve desired shapes efficiently. The capability to produce intricate designs sets lathes apart from other machinery. Skilled operators maximize this potential for high-quality results.

Parts and Components of Lathe Machines

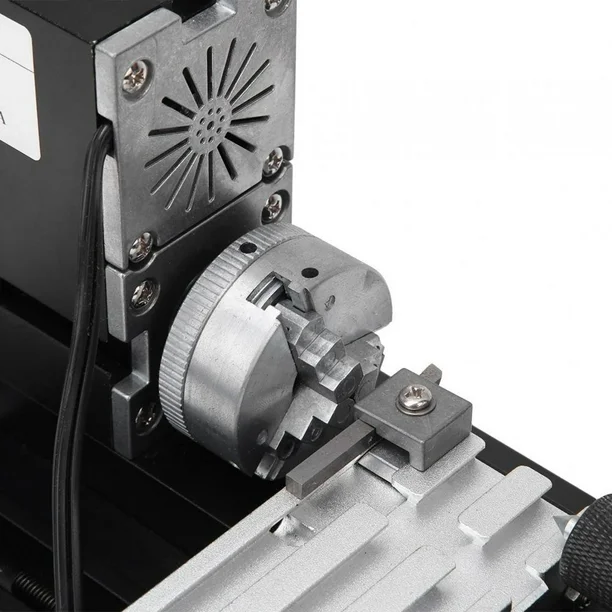

Understanding lathe machines requires knowledge of their components. The headstock is a crucial part. It houses the motor and spindle, allowing rotation of the workpiece. Stability and durability characterize a well-built headstock. This foundation ensures smooth and accurate cutting.

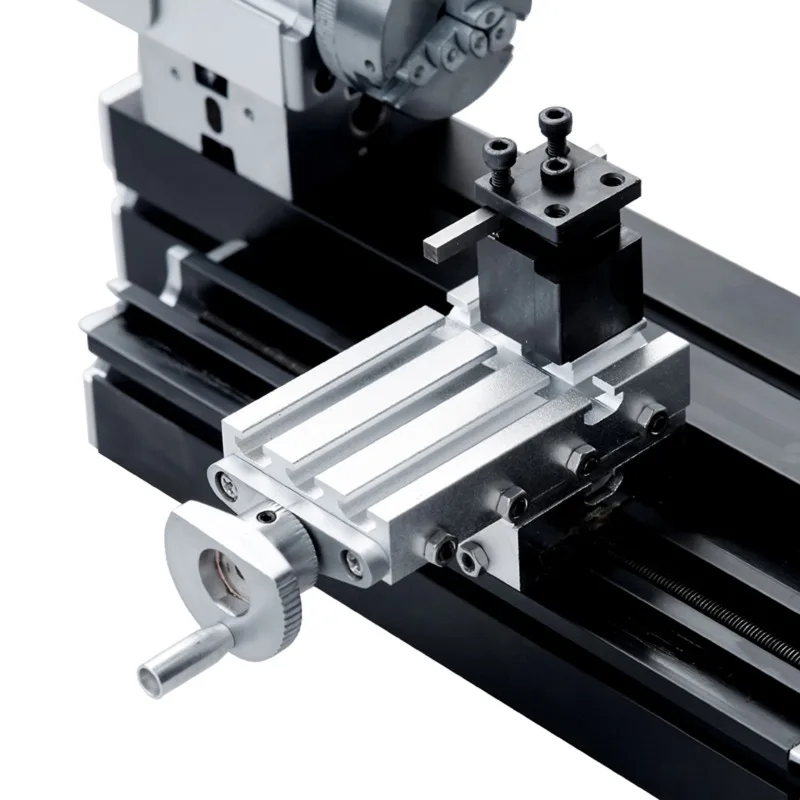

The tailstock supports the other end of the workpiece. Adjustability is its defining feature. Operators can slide it along the bed for proper alignment. This flexibility helps achieve precision during operations. Each component works in harmony for optimal performance.

In addition, the carriage controls the tool’s movement. It enables the tool to traverse the workpiece seamlessly. The different feed rates allow for accurate finishing of parts. A well-functioning carriage enhances the tool’s efficiency and effectiveness.

Lastly, the bed of the lathe machine holds the components. A robust design ensures the machine can withstand vibrations and forces. Each part’s integration contributes to the overall functionality. Understanding these components aids in appreciating lathe operations.

Applications of Lathe Machines

Lathe machines serve myriad applications across various industries. In automotive manufacturing, they produce engine components with precision. Parts like shafts and pistons require tight tolerances. Lathe machines deliver these specifications consistently. As a result, the automotive industry relies heavily on their capabilities.

Moreover, the aerospace sector benefits from lathe machines. Aircraft components demand maximum reliability. Therefore, precision is non-negotiable. Lathe machines create critical parts, ensuring safety and performance. The ability to handle tough materials adds to their appeal in this industry.

In the medical field, lathe machines play an essential role. They manufacture surgical tools and implants. Exact measurements are vital for patient safety. Lathes produce these components with the necessary accuracy. The customization possible with lathe machines opens new possibilities for medical advancements.

Woodworking also benefits from lathe technology. Craftsmen use lathes to produce furniture and decorative items. The artistic designs achievable enhance the aesthetic value of products. Additionally, the ability to create bespoke pieces keeps this sector thriving. Lathe machines connect various industries through their versatility.

The Evolution of Lathe Machines

Lathe machines have a rich history. They date back to ancient civilizations. Initially, lathes operated solely using human power. Craftsmanship defined this era, emphasizing skill and creativity. As time progressed, innovations emerged, changing lathe operations forever.

The Industrial Revolution marked a turning point. Factories adopted steam-powered machines. This advancement significantly increased productivity. Lathes could produce parts faster and more consistently. The focus transitioned from individual craftsmanship to mass production. Automation began shaping the landscape of manufacturing.

As the 20th century approached, electrical lathes became popular. These machines improved efficiency further. Operators enjoyed increased speed and reliability. Furthermore, advancements in materials and technology enhanced lathe durability. Innovations in design allowed for more complex operations.

Today, computer numerical control (CNC) lathe machines dominate the market. These machines rely on software to manage operations. Operators program specific tasks eliminating manual mistakes. The accuracy achieved through CNC technology is unparalleled. The evolution of lathe machines exemplifies humanity’s quest for efficiency and precision.

Maintenance of Lathe Machines

Regular maintenance keeps lathe machines running smoothly. Neglecting maintenance leads to decreased performance. Simple care practices can extend the machine’s lifespan significantly. Operators should follow recommended maintenance schedules diligently.

First, lubrication plays a critical role. Proper lubrication reduces friction between moving parts. This step minimizes wear and tear during operation. Technicians frequently check oil levels and replenish as necessary. Adhering to lubrication guidelines is essential for seamless operations.

Secondly, cleanliness is essential. Dust and debris can hinder the functioning of lathe machines. Regular cleaning helps prevent buildup that may damage components. Operators should prioritize cleanliness before and after operations. A clean workspace promotes efficiency and safety.

Lastly, monitoring alignment and calibration is essential. Misalignment can lead to inaccurate cuts. Regular checks on machine alignment ensure ongoing precision. Technicians should also recalibrate machines as needed. This attention to detail ensures high-quality output consistently.

Safety Measures in Lathe Operations

Safety is paramount in lathe operations. Operators must understand hazards associated with the machine. Proper training ensures awareness of potential risks. Following safety protocols mitigates dangers during operation.

Firstly, wearing protective gear is critical. Safety goggles protect the eyes from flying debris. Gloves keep hands safe from sharp edges. Operators should also wear hearing protection if noise levels are high. Each piece of equipment contributes to a safer working environment.

Secondly, understanding the machine’s controls is essential. Operators must know how to stop the lathe quickly. This knowledge is vital for any emergency situations. Training programs often emphasize familiarization with machine functions.

Lastly, maintaining a clean workspace enhances safety. Clutter around the machine poses risks. Operators should keep the area organized and free of obstructions. Creating a safe environment promotes efficiency and reduces accidents.

The Future of Lathe Machines

The future of lathe machine looks promising. Continuous innovations drive advancements in technology. Emerging trends reflect the need for enhanced precision and automation. These shifts will shape the manufacturing landscape.

Automation will dominate the lathe industry. Computer systems will handle more operations. This transition reduces human error and improves efficiency. As a result, manufacturers can produce higher-quality parts faster.

Additionally, smart technology will influence lathe designs. Integration of IoT (Internet of Things) will enable real-time monitoring. This monitoring enhances predictability and reduces downtime. Operators will gain insights into machine performance like never before.

Finally, sustainability will play a role in lathe advancements. Manufacturers will develop eco-friendly lathes. Reduced energy consumption and waste will become priorities. These changes align with global efforts to minimize environmental impacts.

Conclusion

Lathe machines are indispensable in modern manufacturing. Their precise operations and versatile applications enable various industries to thrive. As technology evolves, lathe machine adapt, enhancing productivity and efficiency. Understanding their components, applications, and maintenance procedures leads to better operations.

Safety measures must be prioritized to ensure smooth operations. With a focus on innovation and sustainability, the future appears bright for lathe machine. These tools will continue to impact manufacturing processes for years to come.

In conclusion, the incredible world of lathe machine holds countless possibilities. As industries evolve, lathe technology will undoubtedly keep changing. The journey of lathe machine showcases humanity’s pursuit of precision and efficiency. Embracing these advancements will foster growth and prosperity for all.