Understanding Carbon Brushes: Essential Components in Electric Motors

Carbon brushes are critical components in many electrical devices. They facilitate the transfer of electrical current between stationary and rotating parts. Without these brushes, devices like electric motors, generators, and alternators would struggle to function efficiently. This blog will explore the importance of carbon brush(カーボンブラシ), their applications, types, and maintenance practices.

What Are Carbon Brushes?

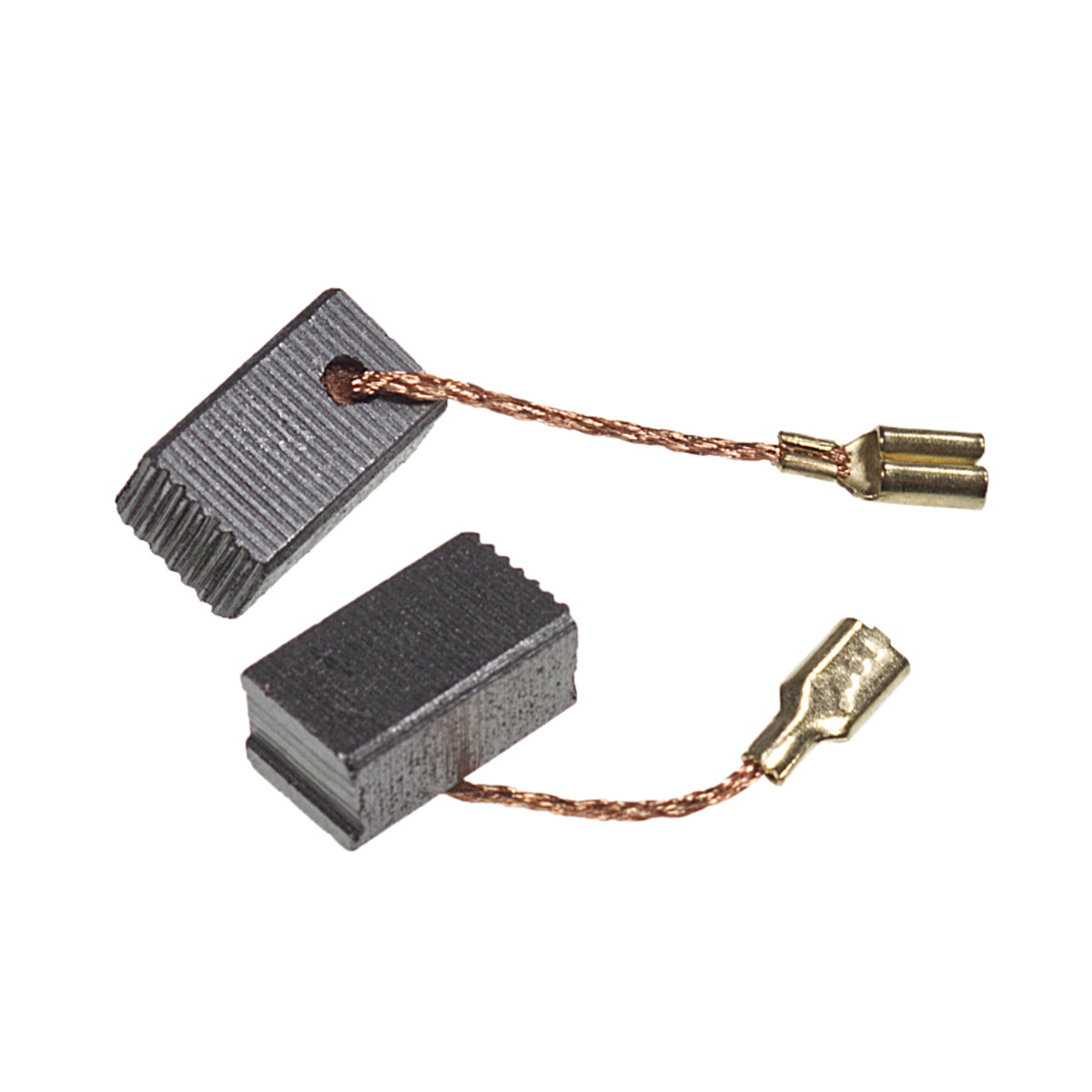

Carbon brushes are small pieces of carbon material. They are usually rectangular or cylindrical in shape. These brushes conduct electricity and are used in conjunction with rotating machinery. Typically, they maintain contact with a rotating shaft. This allows for a continuous transfer of current. The design and composition of carbon brushes vary based on their application.

Moreover, the material composition of carbon brushes greatly influences their performance. Most carbon brushes are made from graphite. However, various additives can be included to enhance their conductivity and durability. The structure of these brushes is essential; it must withstand constant friction and wear.

To ensure efficiency, the brushes must maintain good contact with the rotor. This is crucial for effective power transfer. Poor contact can lead to sparking, overheating, and premature wear. Therefore, selecting the right carbon brush for a specific application is vital for optimal performance.

Furthermore, carbon brushes can be found in various devices, from power tools to industrial machinery. The diversity in applications is a testament to their versatility. Nonetheless, they are often overlooked until a malfunction occurs. Maintenance of these components is essential to ensure longevity and efficiency.

Types of Carbon Brushes

Various types of carbon brushes exist to suit different applications. For instance, some are designed for high-speed motors. Others are tailored for heavy-load applications. Understanding the types can aid in selecting the appropriate brush for each project.

One common type is the electro-graphite brush. This type is made primarily from high-purity graphite. It offers excellent conductivity and heat resistance. Electro-graphite brushes are typically used in generators and small electric motors.

Another type is the resin-bonded carbon brush. These brushes contain resin and are known for their durability. They are highly effective in applications with high wear and tear. They are often used in industrial machinery where extreme conditions are present.

Additionally, there are metal-graphite brushes. These incorporate metal particles into their structure. This type of brush is designed for applications requiring higher conductivity. They are suitable for traction motors and some industrial applications.

Each type of carbon brush serves a specific purpose. Selecting the right type based on the application requirements ensures better performance. Manufacturers usually provide detailed specifications to guide users in choosing the most suitable carbon brush for their devices.

The Role of Carbon Brushes in Electric Motors

Electric motors rely heavily on carbon brushes for efficient operation. These components allow for the transfer of electrical energy to mechanical energy. Consequently, this enables the motor to perform its intended functions. The brushes maintain contact with the commutator. This ensures a continuous flow of electricity to the motor windings.

The design of the motor dictates the brush placement. Proper alignment is crucial for minimizing wear and ensuring efficient power transfer. If the brushes are misaligned, it could result in increased friction. This may lead to overheating and significantly reduce the life span of both the brushes and the motor itself.

In electric vehicles, carbon brushes play a vital role in the drivetrains. They help maintain a consistent power supply to the motor. If these brushes fail, the entire system can come to a halt. This highlights the importance of monitoring the condition of carbon brushes in electric vehicles.

Furthermore, in industrial settings, the failure of a carbon brush can result in costly downtime. Hence, regular inspection and maintenance are essential. This proactive approach allows for the timely replacement of worn brushes. It can prevent unexpected breakdowns that disrupt production.

Finally, carbon brushes also play a role in the overall efficiency of electric motors. Properly maintained brushes ensure optimal performance and reduced energy consumption. This translates to lower operational costs and enhances overall productivity.

Maintenance of Carbon Brushes

Proper maintenance significantly enhances the lifespan of carbon brushes. Regular inspection is essential to check for wear and tear. Over time, brushes can wear down due to friction with the commutator. Therefore, routine checks are necessary to ensure they remain effective.

The first step involves assessing the condition of the brushes. Signs of wear can include uneven surfaces, excessive length wear, or damage. If significant wear is observed, it may be time for replacement. Ensuring that the brushes maintain good contact with the commutator is critical.

Additionally, proper cleaning of the brush and commutator surfaces can improve performance. Dust and debris accumulation can hinder efficient electrical transfer. Routine cleaning helps maintain conductivity and reduces the risk of overheating. Cleaning tools and solvents specifically designed for this purpose are recommended.

Moreover, adjusting the spring pressure applied to the brushes is critical. Proper pressure ensures that the brushes maintain contact without excessive force. Too much force can lead to increased wear, while too little can result in poor conductivity.

Lastly, maintaining the alignment of the carbon brushes is crucial. Misalignment can cause uneven wear patterns and ultimately lead to brush failure. Ensuring that the mounting brackets are secure and the brushes are positioned correctly will help in maintaining longevity.

The Future of Carbon Brushes

The future of carbon brushes is being shaped by advancements in technology. As industries evolve, the demand for efficient electrical components grows. This includes a continuous need for high-performance carbon brushes. Manufacturers are focusing on developing brushes that can withstand more demanding applications.

Emerging materials are being studied to enhance the durability of carbon brushes. Research is being conducted to identify alternatives that can deliver higher conductivity and thermal resistance. These advancements aim to increase the operational lifespan of brushes under extreme conditions.

Another trend is the move towards automated systems in industries. Automation often requires more reliable, long-lasting components. Carbon brushes must adapt by improving their design to meet these evolving needs. Innovations may include alterations in shape, size, and material composition to enhance performance.

Sustainability is also becoming a focal point in the manufacturing of carbon brushes. Advancements in production methods aim to minimize waste and energy consumption. Eco-friendly materials may gradually replace conventional options. This shift aligns with global trends towards reducing industrial waste and improving energy efficiency.

Finally, ongoing research into the effects of wear on carbon brushes will continue. Understanding the wear mechanisms better could lead to better designs and materials. This could prolong the life of carbon brushes while maintaining their efficiency. Future developments will ultimately ensure that carbon brushes remain a key component in electric motors and other applications.

Common Myths About Carbon Brushes

Numerous misconceptions surround carbon brushes. One common myth is that all carbon brushes are the same. In reality, brushes are tailored to specific applications. Different types exhibit unique properties essential for various machines. Misunderstanding this can lead to choosing the wrong brush.

Another myth is that carbon brushes do not require any maintenance. In fact, regular upkeep is crucial. Neglecting maintenance can lead to reduced efficiency and increased costs. Users should regularly inspect and clean the brushes to ensure optimal function.

Some believe that carbon brushes last forever. Brushes inevitably wear down due to friction. Their lifespan can vary depending on usage and environment. Awareness of wear signs can prompt timely replacements, preventing unexpected failures.

Additionally, there’s a misconception that higher-quality brushes are not worth the cost. While premium brushes may be more expensive, they often provide better performance and longevity. Investing in high-quality carbon brushes can result in long-term savings and fewer replacements.

Lastly, there is a belief that all carbon brushes pollute the environment. While traditional brushes may release particles, advancements in manufacturing are mitigating these issues. Manufacturers are increasingly adopting eco-friendly processes to produce carbon brushes.

Conclusion: The Importance of Carbon Brushes

Carbon brush play an indispensable role in various electric devices. Their ability to transfer electrical energy efficiently cannot be overstated. Without these components, many motors and generators would cease to function effectively. Understanding their types, maintenance, and future developments is key to maximizing their benefits.

Proper maintenance practices ensure that carbon brushes perform optimally over time. Regular inspections and timely replacements can prevent costly downtimes. Furthermore, selecting the right type for the specific application is essential for efficiency. Future advancements promise to enhance the performance of these components while addressing environmental concerns.

As technology continues to evolve, so will the innovation surrounding carbon brushes. By investing in quality brushes and maintaining them appropriately, users can significantly improve their devices’ longevity and efficiency.

Understanding carbon brushes leads to better decision-making and improved operational outcomes. This knowledge is crucial for both manufacturers and end-users. Emphasizing the importance of carbon brushes will encourage better practices and innovations in the industry.

In summary, carbon brushes are essential components in the electrical engineering sphere. Their significance cannot be overlooked. The continuous exploration of materials and designs will contribute to their evolution. With diligent attention and proper care, carbon brushes will remain vital in the world of electrical devices.