Introduction to Measuring Tools

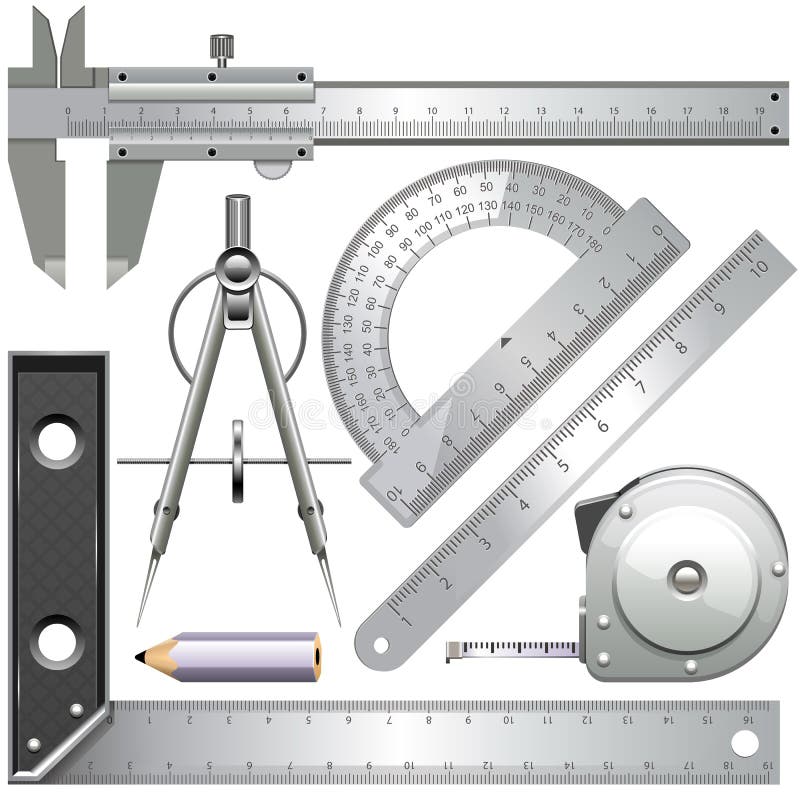

Measuring tools are essential for precision in various tasks and industries. They help ensure accuracy in construction, science, tailoring, and more. These tools range from simple devices, like rulers, to advanced digital instruments. Each type serves a distinct purpose, catering to specific measurement needs.

Using the right measuring tool boosts productivity and minimizes errors. For example, scientists depend on advanced tools for precise data collection, while carpenters use tape measures for projects. With the vast variety available, understanding measuring tools is crucial for selecting the best one for your work.

Measuring tools are categorized into common types, such as rulers, calipers, levels, and specialized tools. These tools come in analog and digital versions, each with unique advantages. Learning about them can greatly improve both personal and professional outcomes. A good grasp of measuring tools can make tasks easier and more effective.

Importance of Accurate Measurements

Accurate measurements are the foundation of successful projects. They impact quality, safety, and performance. Whether in construction, science, or crafting, precision is crucial for achieving desired results.

Ensures Quality and Consistency

Precise measurements ensure consistent work with high quality. For example, in construction, accurate dimensions guarantee proper fitting of components. Similarly, in tailoring, exact measurements lead to well-fitted garments. Consistency reduces errors and enhances overall output.

Promotes Safety

Accurate measurements help maintain safety in various fields. In engineering, precise calculations prevent structural failures. In laboratories, correct measurements ensure proper mixing of chemicals, avoiding dangerous reactions.

Optimizes Resource Usage

With precise measurements, you use resources efficiently. This reduces material waste and saves costs. For example, woodworking projects with exact dimensions eliminate excessive scrap.

Drives Efficient Problem-Solving

Accurate data aids in identifying and fixing issues quickly. This ensures smooth work progress. In scientific research, precise measurements allow the replication and validation of experiments. This supports the advancement of knowledge.

Focusing on accuracy in measurements improves the outcome of any task. Using the right measuring tools makes this achievable.

Common Types of Measuring Tool

Measuring tools come in various types to suit different needs. Each tool has specific uses and benefits. Below are four common categories of measuring tools, each essential for precise work.

Rulers and Tape Measures

Rulers and tape measures are basic but necessary tools. They help measure lengths and distances easily. Rulers are ideal for small-scale tasks like drawing and crafting. Tape measures are versatile for larger jobs, such as construction and furniture making. They often feature markings in inches and centimeters for accurate measurement.

Calipers and Micrometers

Calipers and micrometers are essential for precision measurement. They are perfect for tasks requiring close tolerances, such as metalwork. Micrometers, on the other hand, measure thicknesses and diameters with extreme accuracy. These tools are popular in machining and engineering.

Protractors and Angle Finders

Protractors and angle finders measure angles precisely. They are simple to use for creating and verifying angles. Angle finders, often digital, are perfect for construction projects. They help ensure beams and joints are aligned correctly.

Levels and Laser Measuring Tools

Levels and lasers are crucial for ensuring straight lines and proper alignment. They eliminate unevenness in shelves, tables, and flooring. Laser measuring tools offer advanced functionality. They quickly measure distances and align items with high precision, making them ideal for both DIY and professional use.

Understanding each type of measuring tool helps you choose the most suitable one for the task. Using the right tool ensures accuracy and efficiency in your work.

Specialized Measuring Tool for Specific Tasks

Certain tasks require specialized measuring tools for precise results. These tools are tailored for specific industries and applications. Here, we explore tools used in woodworking, science, tailoring, and sewing.

Measuring Tools for Woodworking and Construction

Woodworking and construction demand tools suited for large-scale and detailed measurements:

- Combination Squares: Essential for checking flatness and angles during woodworking.

- Stud Finders: Locate hidden structures in walls, ensuring safe drilling or mounting.

- Chalk Line Tools: Mark long, straight lines on surfaces for accurate alignment.

- Plumb Bobs: Assess vertical alignment, especially in construction tasks.

These tools enhance precision, prevent errors, and ensure structural integrity in your projects.

Measuring Tools for Science and Laboratories

Science and lab work require intricate measuring instruments for accuracy:

- Graduated Cylinders: Measure liquid volumes with precision.

- Spectrometers: Analyze light properties, crucial in scientific studies.

- Thermometers: Monitor temperature for experiments.

- Laboratory Scales: Provide exact weights for reagents.

Such tools ensure reliable data and safe operations in laboratory settings.

Measuring Tools for Tailoring and Sewing

Tailoring and sewing rely on tools for accurate measurements and cuts:

- Measuring Tapes: Flexible for measuring fabric dimensions.

- Seam Gauges: Measure stitch spaces for neat finishes.

- French Curves: Create precise patterns for garment designs.

- Dressmaking Templates: Standardize clothing dimensions.

These tools are indispensable for creating well-fitting clothes and detailed designs.

Using specialized measuring tools improves precision in industry-specific tasks, ensuring success every time.

Digital vs. Analog Measuring Tools: Pros and Cons

Choosing between digital and analog measuring tools depends on your needs. Both have unique benefits and limitations. Here’s a comparison to help you decide:

Advantages of Digital Measuring Tools

- High Precision: Digital tools display exact measurements in real time.

- User-Friendly: Easy-to-read screens simplify interpretation of results.

- Advanced Features: Some models store data and perform complex calculations.

- Versatile Applications: Ideal for tasks requiring extreme accuracy, like engineering or scientific research.

Disadvantages of Digital Measuring Tools

- Power Dependency: Most tools need batteries, which can run out unexpectedly.

- Higher Costs: Digital tools are typically more expensive than analog ones.

- Fragility: They may be less durable in rough conditions.

Advantages of Analog Measuring Tools

- Cost-Effective: Analog tools are affordable and widely available.

- Reliable: They don’t need batteries or power sources to function.

- Durable: With fewer electronic parts, they withstand rough handling well.

- Simple Design: Easy to use and maintain without technical knowledge.

Disadvantages of Analog Measuring Tools

- Limited Accuracy: Readings may not be as precise as digital options.

- Subject to Error: Human interpretation can lead to inaccuracies.

- Lack of Advanced Features: No data storage or smart functionalities.

Choosing Between Digital and Analog

Consider the task, environment, and budget when selecting a measuring tool. Digital tools offer precision and convenience, but analog tools provide simplicity and reliability.

Tips for Choosing the Right Measuring Tool

Selecting the right measuring tool is critical for achieving precision in your tasks. With various options available, understanding key factors can guide your decision.

Identify Your Measurement Needs

Assess the specifics of your task before choosing a tool. For example:

- Length or distance measurement: Use rulers or tape measures.

- Precise thickness or diameter: Opt for calipers or micrometers.

- Angle measurement: Use protractors or angle finders.

- Alignment and straightness: Choose levels or laser tools.

Clearly defining your requirements ensures the tool matches your purpose.

Consider the Environment

Pick tools suitable for your working conditions. Analog tools work well outdoors due to their durability. Digital tools are best for controlled environments to prevent damage and ensure accuracy.

Evaluate Ease of Use

Select tools that are easy to operate and interpret. Beginners may prefer simple analog tools. Advanced users might benefit from digital tools with additional functionalities.

Check Precision and Durability

High-precision tasks need tools specifically designed for accuracy, such as micrometers or spectrometers. For heavy-duty use, durable tools like tape measures with reinforced casings are ideal.

Budget Factors

Keep your budget in mind while selecting. Analog tools are typically more affordable. Digital tools offer advanced features but are costlier.

Explore Versatility

Tools with multiple functions are valuable for diverse projects. For example, combination squares can measure angles and check flatness.

Thinking through these points can help you find the right measuring tool for your needs.

Proper Maintenance and Calibration of Measuring Tool

Proper care of measuring tools ensures accurate results and extends their lifespan. Regular maintenance and calibration are vital for keeping these tools efficient and reliable.

Importance of Maintenance

- Prevents Wear and Tear: Routine cleaning avoids damage from dust or debris.

- Ensures Longevity: Good upkeep delays tool replacements.

- Improves Accuracy: Well-maintained tools provide consistent and precise readings.

Best Practices for Maintenance

- Clean After Use: Wipe tools to remove dirt or moisture.

- Store Properly: Keep tools in dry and secure spaces.

- Inspect Regularly: Check for damages or loose parts.

- Lubricate Moving Parts: Apply oil to prevent rust and ensure smooth operation.

- Avoid Dropping Tools: Handle them carefully to prevent misalignment or breakage.

Importance of Calibration

- Guarantees Precision: Calibration aligns tools with standard measurements.

- Complies with Standards: Ensures tools meet industry and safety requirements.

- Detects Errors Early: Regular checks prevent inaccurate results.

How to Calibrate Measuring Tools

- Follow Manufacturer Guidelines: Refer to manuals for correct calibration steps.

- Use Calibration Equipment: For advanced tools, employ professional calibration devices.

- Regular Schedule: Perform calibration at fixed intervals, such as monthly or annually.

- Consult Experts: Hire professionals for calibrating complex tools like spectrometers.

Keeping measuring tools well-maintained and calibrated ensures reliability and enhances task precision. Proper care saves costs on unnecessary replacements and improves project outcomes.

Specialty Measuring Tool

Understanding Specialty Tools for Specific Industries

In addition to the standard measuring tools, there are specialized tools designed for specific trades and industries that require unique measurement capabilities. For instance, in the field of engineering, measuring tools like micrometers provide incredibly precise measurements, often down to the thousandths of a millimeter. Similarly, in carpentry, a framing square is essential for ensuring that corners are square and measurements are accurate when constructing structures. In the realm of tailoring and sewing, a tape measure specifically made from soft materials allows for flexible measurements around curves. Recognizing the need for specialty tools can greatly enhance the accuracy of work within various professional contexts while also improving efficiency.

Factors to Consider When Choosing Specialty Tools

When selecting specialty measuring tools, there are several key factors to consider. First, assess the precision required for your specific tasks. Different projects demand different levels of accuracy, so understanding your project requirements will help guide your choices. Second, consider the material and construction of the tool; durable materials will withstand wear and tear better than cheaper alternatives. Finally, evaluate the user-friendliness of the tool. A complicated tool can slow you down and increase the risk of errors, while a simple, intuitive design can save time and enhance efficiency. Consider also the calibration and maintenance needs of specialized tools. Investing in quality specialty measuring tools not only improves your work but also saves you from frequent replacements due to wear or malfunction.

Safety Considerations

Ensuring Safety While Using Measuring Tools

While measuring tools are designed for accuracy, safety should also be a critical consideration. Improper use of tools can lead to accidents or damage that can compromise both your work and well-being. For example, sharp edges on measuring tools like utility knives or blades should always be handled with care. To prevent cuts or injuries, use protective gloves when necessary and always ensure tools are stored properly. Furthermore, when using tools that require physical exertion or extensive bending, maintaining proper posture can help prevent strain injuries. Familiarizing yourself with the specific safety guidelines of each tool will ensure a safer working environment.

Promoting Care and Maintenance for Longevity

Maintaining safety doesn’t just come from handling tools correctly; it also involves caring for them properly. Regular maintenance, such as checking for any signs of wear or damage, can prevent accidents before they happen. Ensure that tape measures retract without issues, calipers open and close smoothly, and levels are appropriately calibrated. Additionally, clean your tools after each use to remove any dust or debris that may accumulate. Proper care extends the life of your tools and enhances their accuracy, which is essential for your projects. By promoting a culture of safety and maintenance, you not only protect yourself but also ensure a more efficient and accurate working environment.

Conclusion: Enhancing Efficiency with the Right Tools

Measuring tools are vital for achieving precision in any task or industry. Selecting the right tool based on your specific needs enhances accuracy and efficiency. From basic rulers to advanced laser tools, each serves a unique purpose. Digital and analog tools both offer benefits, catering to diverse requirements.

Accurate measurements improve quality, ensure safety, and optimize resources. Specialized tools for woodworking, science, and sewing provide tailored solutions for detailed tasks. Proper maintenance and calibration keep tools functional and reliable for extended use.

Investing time in understanding measuring tools and their applications boosts productivity and minimizes errors. By choosing and maintaining the right tools, you can achieve better results and streamline your work.