Introduction to Concrete Cutting Saws

Concrete cutting saws are vital tools for contractors. These powerful devices slice through hardened concrete with precision. Such a task could be for creating openings for plumbing or electrical installations. Cutting concrete demands robust equipment, and concrete cutting saws fit this need perfectly.

Contractors use these saws in various projects, including demolition and renovation. The saws feature specialized blades made to tackle the toughness of concrete. This ensures that each cut is clean, reducing the need for additional finishing work.

When choosing concrete cutting saws, it’s critical to understand their potential. These machines offer high efficiency and the ability to cut through different depths. They can also handle various types of concrete, from soft to reinforced. Knowing your project requirements is key to selecting the right saw.

For those new to concrete cutting, selecting the right saw can be challenging. There are several types of saws, each designed for specific tasks. The main types include hand-held saws, walk-behind saws, and wire saws. Each type has its advantages and is best suited to particular situations.

In the next sections, we will go deeper into the types of concrete cutting saws available. We’ll look at essential features to consider before buying, and share safety tips. We’ll also cover maintenance advice and best practices for efficient cutting. Lastly, we’ll review some popular brands and models that contractors trust.

Types of Concrete Cutting Saws

When tackling a concrete cutting project, choosing the right type of saw is crucial. There are generally three types of concrete cutting saws used by contractors. Each type offers distinct features and benefits suited to various applications and project sizes. Let’s explore these types to help you make an informed decision.

Hand-Held Saws

Hand-held saws top the list for versatility and mobility. These compact saws work well for small jobs. You can use them on walls, floors, and even overhead. Being lightweight, they allow for easy transportation. They fit tight spaces, making precise cuts in hard-to-reach areas. Hand-held saws use electric, hydraulic, or gas-powered motors.

For jobs like cutting pipes or creating joints, hand-held saws are ideal. They are often the first choice when quick, straightforward cutting is necessary. However, for deeper or longer cuts, other types of saws may be more suitable.

Walk-Behind Saws

These saws are perfect for large projects. They cut deep into concrete and are a go-to for floor and road work. Walk-behind saws come in different sizes. Some are small and can fit in confined spaces. Others are large, requiring more space to operate.

Walk-behind saws provide straight, deep cuts and are useful for lengthy cutting jobs. Workers push them from behind, hence the name. These saws offer stability and can cut through thick concrete efficiently.

Many walk-behind saws feature depth adjustment controls. This allows for precision when setting the desired depth. They are also less tiring to use on big tasks compared to hand-held saws.

Wire Saws

Wire saws are special tools for complex cutting jobs. They use a metal wire, infused with diamond segments, to cut through concrete. This saw type is excellent for large sections or where there’s a need for very precise cuts.

Wire saws can handle irregular shapes and sizes. They are often the go-to for demolition work. These saws cause minimal disruption and are a safe choice for sensitive cutting environments. Wire saws are also known for their ability to cut through heavily reinforced concrete.

Using a wire saw requires more skill and setup but delivers unparalleled precision. For huge and intricate cutting projects, wire saws are the best option.

Essential Features to Consider Before Buying

When selecting a concrete cutting saw, it’s important to pay attention to certain key features. These features can greatly impact the saw’s performance, and choosing the right ones can ensure you have the right tool for your project. Below, we’ll highlight the critical features you should consider before making your purchase.

Power Source

The power source of a concrete cutting saw determines its mobility and the kind of environments where it can be used. Generally, you have three options:

- Electric: Ideal for indoor use as they don’t emit fumes and are relatively quiet.

- Gas-powered: Better for outdoor or well-ventilated areas due to emissions, with the advantage of not being tethered to an electric outlet.

- Hydraulic: These are less common, but offer powerful cutting capability and often require less maintenance.

Consider the project’s location and power availability when choosing the power source.

Blade Type

Blade type is another critical feature to consider as it affects the quality and speed of the cut.

- Diamond blades: These are the most effective for concrete, providing a quick, clean cut.

- Abrasive blades: These can be cheaper but may not last as long or cut as effectively.

Your choice should reflect the hardness of the concrete you’re cutting and the precision required for the job.

Depth of Cut

Depth of cut is pivotal because it determines how deep the saw can slice through the concrete.

- Choose a saw with adjustable depth settings for versatility across various project requirements.

- It is vital to ensure that the saw’s depth capacity meets the requirements of your specific cutting tasks.

Whether it’s for large scale demolition or precise modifications, the depth of cut is a feature that directly influences your work’s efficiency. Take the time to match the saw’s capacity with the demands of your jobs to ensure optimal results.

Safety Tips for Operating Concrete Cutting Saws

Safety should always come first when operating concrete cutting saws. To help minimize risk and ensure a safe working environment, here are some vital safety tips every contractor should follow:

Wear Appropriate Personal Protective Equipment (PPE)

Always wear the necessary PPE. This includes:

- Eye protection: to shield against flying debris.

- Ear protection: to guard against loud noise from the saw.

- Dust masks or respirators: especially when cutting dry concrete to avoid inhaling dust.

- Heavy-duty gloves: to protect hands from vibrations and abrasions.

- Steel-toed boots: to keep feet safe from falling objects.

Inspect the Equipment Before Use

Check the saw and blades for any damage before starting your work. Ensure all parts are secure and in good working condition.

Be Aware of Your Surroundings

Be mindful of people and obstacles in your work area. Keep onlookers at a safe distance. Look out for any hazards that could cause accidents.

Use the Saw Correctly

Follow the manufacturer’s instructions. Do not force the saw or use it for a purpose it’s not designed for. Work at a pace that allows for control and precision.

Maintain a Firm Grip and Stance

A secure grip and stable stance are important. They help you control the saw and prevent slips and trips.

Avoid Twisting the Blade During a Cut

Twisting can damage the blade and cause kickback. Always aim for a straight cut.

Ensure Adequate Ventilation for Gas-powered Saws

Avoid using gas-powered saws in enclosed spaces to prevent the buildup of harmful fumes.

Stay Alert and Focused

Don’t operate a concrete cutting saw while tired or under the influence of drugs or alcohol. Always be alert to the saw’s performance and how it’s responding to the concrete.

Keep a First Aid Kit on Hand

Always have a first aid kit available for immediate response to any injuries.

By following these safety tips, contractors can reduce the risk of accidents and ensure that their use of concrete cutting saws is both safe and effective.

Maintenance and Care for Longevity

Proper maintenance and care can greatly extend the life of concrete cutting saws. Here’s how you should approach it.

Keep Blades Sharp and Intact

Sharp blades make cutting easier and safer. Check blades regularly for wear. Replace them as necessary.

Clean the Saw After Each Use

Remove concrete dust and debris after every job. This helps prevent buildup that can damage the saw.

Regularly Check for Loose Parts

Vibration during cutting can loosen parts. Tighten bolts and screws often to ensure safety and optimal performance.

Lubricate Moving Parts

Apply lubrication to moving parts according to the manufacturer’s instructions. Proper lubrication reduces friction and wear.

Inspect Cords and Connections

For electric saws, inspect cords for damage. Check connections to make sure they are secure.

Store Saws Correctly

Store saws in a dry, clean space to protect them from the elements and rust.

Follow Manufacturer’s Maintenance Schedule

Each saw has a specific maintenance schedule. Adhere to it for best results.

Have the Saw Serviced Regularly

Professional servicing can catch issues early. It can prevent costly repairs down the line.

By keeping up with these maintenance tasks, your concrete cutting saws will be more reliable and last longer. Always refer to your saw’s user manual for specific care instructions suited to your model. Maintain your tools well, and they will serve you efficiently for many jobs to come.

Best Practices for Efficient Concrete Cutting

To achieve efficient and effective concrete cutting, consider adopting some best practices:

- Plan your cuts: Before starting, plan your cut lines. Mark them clearly.

- Choose the right saw: Match the saw type to the job. Hand-held for small, walk-behind for large, and wire saws for precision.

- Use sharp blades: Always begin with a sharp diamond blade for quick, clean cuts.

- Maintain proper speed: Don’t rush. Cut at a steady speed that the saw can handle.

- Ensure water supply: If using a wet cutting method, maintain a consistent water flow to reduce dust and cool the blade.

- Monitor blade temperature: Overheating can damage blades. Pause regularly to prevent this.

- Support the material: Secure the concrete to prevent shifting while cutting.

- Check the saw’s alignment: Regularly ensure the blade is aligned for straight cuts.

- Operate with care: Handle the saw with skill to avoid kickback and ensure smooth cuts.

- Clean up after cutting: Remove debris and dust to maintain a clear working area.

By sticking to these practices, contractors can cut concrete more efficiently, saving time and resources.

Popular Brands and Models of Concrete Cutting Saws

When shopping for concrete cutting saws, you will encounter various brands. Each offers models with unique features and benefits. Here are some of the leading brands and their popular models that contractors trust and use widely.

Stihl

Stihl is renowned for its range of outdoor and construction tools. Their concrete cutting saws are robust and reliable. The Stihl TS 440 is popular among contractors. It stands out for its versatility and precision in cutting concrete.

Husqvarna

Husqvarna is another top brand in this category. Their saws are known for their durability and ease of use. The Husqvarna K 770 is a favorite. It offers a powerful cut and smooth operation for all-day use.

Hilti

Hilti concrete saws provide advanced technology and performance. The Hilti DSH 700-X is a hand-held gas saw that contractors choose for its power and portability.

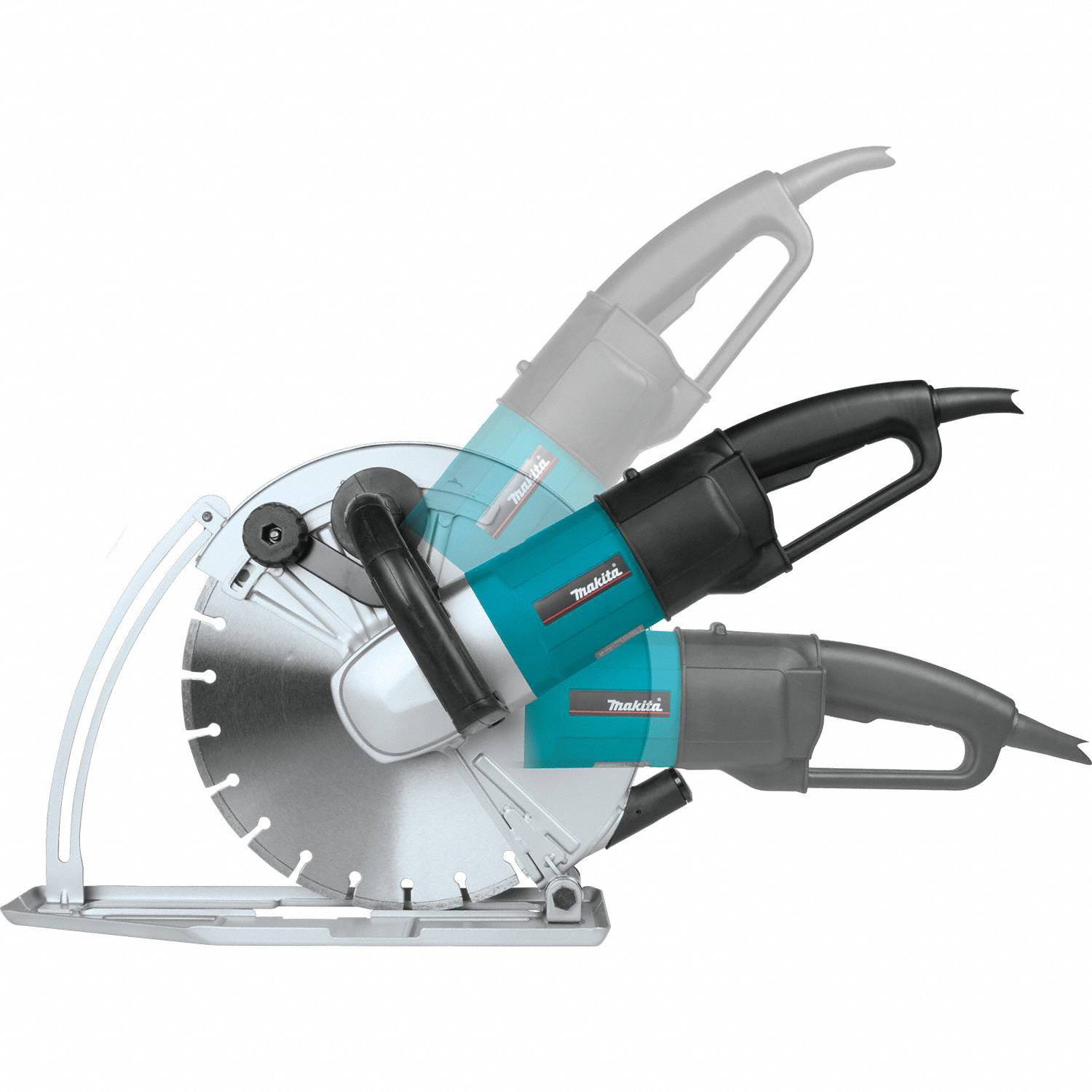

Makita

Makita offers a range of electric saws that are ideal for indoor use. The Makita EK6101 is a lightweight model. It is perfect for quick cuts and small to medium jobs.

DeWalt

DeWalt is popular for its construction tools across various trades. Their concrete saws, like the DeWalt DCS690X2, offer cordless convenience with a battery-powered design that delivers strong performance.

It is important to remember that each saw caters to different needs. Some are better for quick, small cuts, while others excel in large-scale projects. Always consider the types of jobs and the materials you typically work with. This will guide you in choosing the right model. Also, consider after-sale service and the availability of parts when making your decision. A good saw with reliable support can make a significant difference in your cutting tasks.