Introduction to Rock Saws

Rock saws are powerful tools in construction. These saws cut through rock with precision and ease. Builders and engineers prefer them for many projects. Rock saws have evolved to meet various needs in construction. They make tasks like trenching, excavation, and demolition quicker. Their design includes sharp, durable blades that grind through hard materials. Modern rock saws also come in different types. Each type suits specific tasks on construction sites. We use rock saws in infrastructure projects like roads and pipelines. They are also vital for landscaping and mining operations. Their usage results in significant time and labor savings.

Rock saws stand out for their efficiency and safety features. They have changed how we approach tough construction challenges. We will explore how these tools have revolutionized the industry. We will discuss the types of rock saws, their uses, and future trends. Stay tuned as we dive into the world of rock saws, a key to modern construction.

The Evolution of Rock Saws in Construction

Rock saws have come a long way from their humble beginnings. In the past, construction relied on manual labor with basic tools that were both time-consuming and physically demanding. The first rock saws introduced a new era, harnessing mechanical power to cut through stone and other hard materials. A simple, yet significant leap from pickaxes and manual chisels, these early machines were bulky and required extensive setup.

Over time, innovations have driven the development of more sophisticated rock saws. Engineers have made significant strides in blade technology. This includes the introduction of diamond-tipped blades which provide durability and precision unheard of in earlier versions. Moreover, the machinery itself became more versatile and mobile, enabling use in a wider range of environments and applications.

Another breakthrough was the integration of hydraulic systems. These systems allowed for greater force and control, enabling rock saws to slice through harder materials with more precision. Furthermore, the advent of remote-controlled and automated rock saw technology has further revolutionized the construction industry. Such advancements have made it possible to operate in hazardous or hard-to-reach areas without compromising worker safety.

Today’s rock saws embody the pinnacle of this evolution. They are lighter, faster, and more efficient than ever, and innovation continues, ensuring that these tools remain indispensable in modern construction. The evolution of rock saws reflects the industry’s ongoing commitment to improving efficiency, safety, and the ability to tackle complex projects with ease.

Types of Rock Saws and Their Uses

Different types of rock saws cater to varied construction needs. Each type has unique features suited to specific tasks. Knowing these can help select the right tool for a job. Here are some common rock saw types and their common uses in construction.

Hand-Held Rock Saws

These are the most portable rock saws. Workers can carry and use them in tight spaces. They are ideal for small cutting jobs like shaping stones or making adjustments on site.

Road Saws

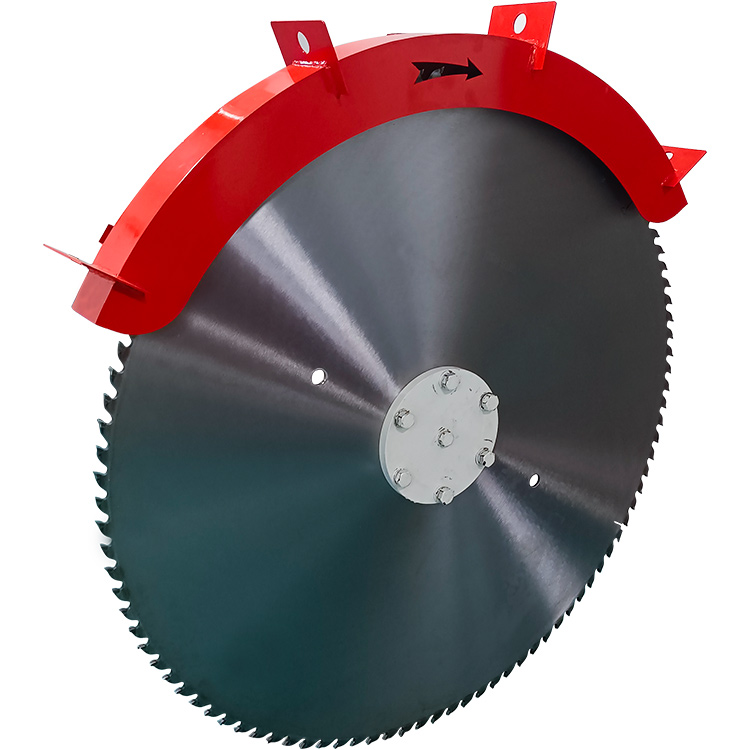

Road saws are heavy-duty and designed for cutting pavement, asphalt, and concrete. They are common in road construction and repair work. Their large blades cut deep, straight lines efficiently.

Wall Saws

Wall saws make precision cuts in vertical surfaces. They’re perfect for creating openings in walls, such as windows or doorways. Their design allows for smooth and straight cuts.

Wire Saws

Wire saws use a metal wire embedded with diamonds. They are for cutting large sections of rock or concrete. Workers often use them when dismantling large structures.

Ring Saws and Chain Saws

These saws use a looped blade, either a chain or ring with cutting segments. They are good for deep cuts in confined areas. They are often used in masonry and demolition.

Rock Saws in Excavation and Trenching

Specialized rock saws are used for excavation and trenching. They cut through rock with precision, ideal for laying pipes or cables. Their designs vary, from smaller machines for tight areas to larger models for open sites.

Each type of rock saw offers unique benefits. For example, hand-held saws provide maneuverability, while road saws deliver power for tough materials. Wall saws offer precision, and wire saws handle large-scale projects well. Ring and chain saws fill the need for deep and exact cuts. Rock saws in excavation and trenching make these tasks faster and less labor-intensive. When choosing a rock saw, it is crucial to match the tool to the job’s requirements. This ensures efficiency and effectiveness on the construction site.

Technological Advancements in Rock Saw Design

Rock saw design has seen striking advances in recent years. The focus has been on increasing efficiency and safety while reducing environmental impact. Rock saws have become more sophisticated with the integration of various technologies. Here are key advancements that have enhanced rock saw capabilities.

Enhanced Materials for Blades

The blades of rock saw now often feature diamond or carbide tips. These materials prolong blade life and maintain sharpness. They allow for cutting through the hardest materials with less effort.

Precision Control Systems

Modern rock saw have precision control systems. These systems give operators better control over the cutting process. It ensures accuracy and reduces the chance of errors.

Automation and Robotics

Automation has entered the realm of rock saw. Some models have robotic features. These features allow for unmanned operation. This is safer for workers, especially in hazardous environments.

Vibration Reduction Technology

Advancements in design have led to reduced vibration. This makes rock saws more comfortable to use. It also lowers the risk of long-term injury for operators.

Improved Energy Efficiency

Newer rock saw models are more energy-efficient. They use less power and still deliver high performance. This helps in reducing the carbon footprint of construction activities.

Noise Reduction Features

Noise is a significant concern on construction sites. Modern rock saws come with features that minimize sound output. Quieter operation is less disruptive and better for worker health.

These technological advancements contribute to the appeal of rock saws in construction. They have made rock saws more reliable and easier to handle. Moving forward, we can expect ongoing innovation in design. This will further revolutionize how construction tasks are tackled.

Rock Saws and Safety in Construction Sites

Safety is paramount on any construction site, and rock saw contribute significantly to this priority. With the integration of advanced safety features, rock saw have seen enhancements that allow workers to tackle challenging tasks with less risk. Here are the key ways in which rock saws enhance safety in construction environments:

- Protective Designs: Modern rock saw come with built-in guards and protective covers. These elements shield operators from flying debris and moving parts.

- Remote Operation Capabilities: Advanced rock saws offer remote control options. This allows operators to work from a safe distance, especially in unstable or hazardous areas.

- Improved Ergonomics: The design of rock saw now considers operator comfort to prevent strain and injury. Handles and control panels are positioned to reduce fatigue and increase control.

- Emergency Stop Functions: Many rock saws have emergency stop buttons. In the event of an issue, the saw can be quickly and easily deactivated to prevent accidents.

- Reduced Dust Exposure: Dust suppression systems are now common in rock saw. Such systems limit the amount of airborne particles, protecting worker lungs and visibility.

- Enhanced Training and Manuals: Manufacturers provide detailed guides and training. This ensures that operators fully understand how to handle rock saws safely.

By prioritizing safety through the aspects listed above, rock saw usage contributes to a more secure work environment. These improvements have played a role in reducing construction site incidents and injuries, and are an integral part of maintaining high safety standards in the construction industry.

Efficiency and Productivity Gains with Rock Saw

Rock saw bring marked improvements in efficiency and productivity to construction sites. When we compare the time and labor needed for traditional methods, rock saw stand out distinctly. Here are several ways these tools boost performance in the field.

- Reduced Labor Costs: Rock saw cut with speed and precision, requiring fewer workers for each task. This leads to a direct reduction in labor costs.

- Faster Completion Times: Tasks that once took days can now be completed in hours with rock saw. This rapid execution allows projects to move forward without delay.

- Minimal Maintenance: Modern rock saw demand less maintenance, keeping them in action longer. This uptime ensures continuous work flow.

- Versatility on Site: Various rock saw types handle numerous tasks. This eliminates the need for multiple specialized tools, saving time in tool switching.

- Increased Accuracy: Precision in cutting reduces material waste and the need for additional corrections. Fewer do-overs mean projects stay on track.

- Enhanced Capability: Rock saws tackle materials that manual tools cannot. They open up possibilities for more complex and creative construction projects.

Because of these advantages, rock saws are a favored choice for cost-conscious and time-sensitive projects. They represent a leap forward in how we approach construction work. As tools become more advanced, these benefits will likely increase, pushing the industry toward even greater productivity and efficiency.

Environmental Impact of Using Rock Saw

With every technological advance in construction, the environmental impact is a crucial factor to consider. Rock saws, while boosting productivity and safety, also come with environmental considerations. Here are key points addressing the environmental aspects of using rock saws in construction:

- Reduction in Greenhouse Gas Emissions: Modern rock saw are more energy-efficient, leading to a decrease in greenhouse gas emissions compared to older models or traditional methods.

- Less Noise Pollution: Noise reduction features in the latest rock saw designs contribute to quieter construction sites, which means less disruption to the surrounding environment and wildlife.

- Dust Control Systems: The implementation of dust suppression systems in rock saws helps in minimizing air pollution. This lessens the impact on air quality and reduces health risks for both workers and nearby residents.

- Reduced Vibration: Advanced rock saws are designed to lower vibration levels, which can reduce soil disruption and the impact on nearby structures and ecosystems.

- Recyclable and Reusable Materials: Many rock saw manufacturers focus on using recyclable components and promote the reuse of materials, aiming to minimize waste in construction.

As we move forward, it is essential that developments in rock saw technology continue to address environmental concerns. Emphasizing sustainable practices will help ensure that the benefits of these powerful tools are not overshadowed by negative ecological effects.

Future Trends in Rock Saw Technology

The construction industry continues to innovate, and rock saw technology is no exception. Looking ahead, several trends seem to be shaping the future of rock saws.

- Further Automation: Expect to see even more sophisticated automated and remotely operated rock saw. This will improve safety and precision in challenging environments.

- Enhanced Blade Materials: The quest for longer-lasting, more efficient blades will continue. Future blades may use advanced materials for even better performance.

- Integration with AI: Artificial intelligence could be used to guide rock saws for optimal cutting patterns, reducing waste and improving speed.

- Eco-Friendly Designs: As environmental concerns grow, rock saw will likely evolve to be more sustainable. This includes reducing energy consumption and using eco-friendly materials.

- Improved Mobility: Rock saw will become more mobile and easier to transport. This will ensure they can be quickly moved to where they’re most needed on site.

- Smart Monitoring Systems: Sensors and monitoring systems will provide real-time data. This will allow for better maintenance schedules and prevent downtime.

These trends indicate a future where rock saws are even more integral to construction processes. They point towards a smarter, safer, and more sustainable construction environment. Rock saw will continue to evolve, bringing about significant advances on construction sites worldwide.